Recently, a lot of attention has been given to atmospheric cold plasma (ACP), as a novel non-thermal approach to sterilization of post-harvest products. Dielectric barrier discharge (DBD) is the method used for plasma generation, along with the gas containment capabilities of the sealed package to create a local plasma field inside the package. HVACPs have the ability to generate unique profiles of bactericidal species in common gases such as air, including radicals, positive and negative ions, and quanta of electromagnetic radiation (Laroussi & Leipold, 2004; Lerouge et al., 2001). The benefits of ACP treatment include the shorter treatment times which reduce impact on product quality and leave no chemical residue (Misra et al., 2011, Schluter, et al., 2013, Thiurmdas et al., 2015, Sarangapani et al. 2015).

One of the PHEED research team’s major objectives is the:

- Optimization of atmospheric cold plasma technologies to reduce microbiological contaminants in food and feed products for increased shelf-life.

- Plasma treatment of fresh produce and other food and feed commodities

- Microbiological and mycotoxin (including Aflatoxin and Fumonisin) reduction in stored grains and food commodities

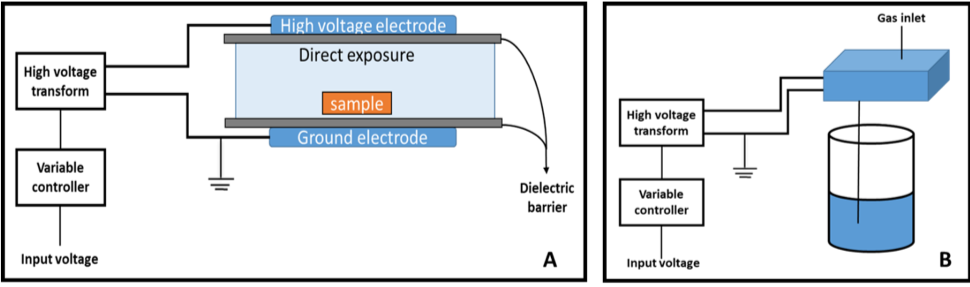

Our system (adapted from Klockow & Keener):

Schematic diagram of a high voltage atmospheric cold plasma system for (A) packaged products

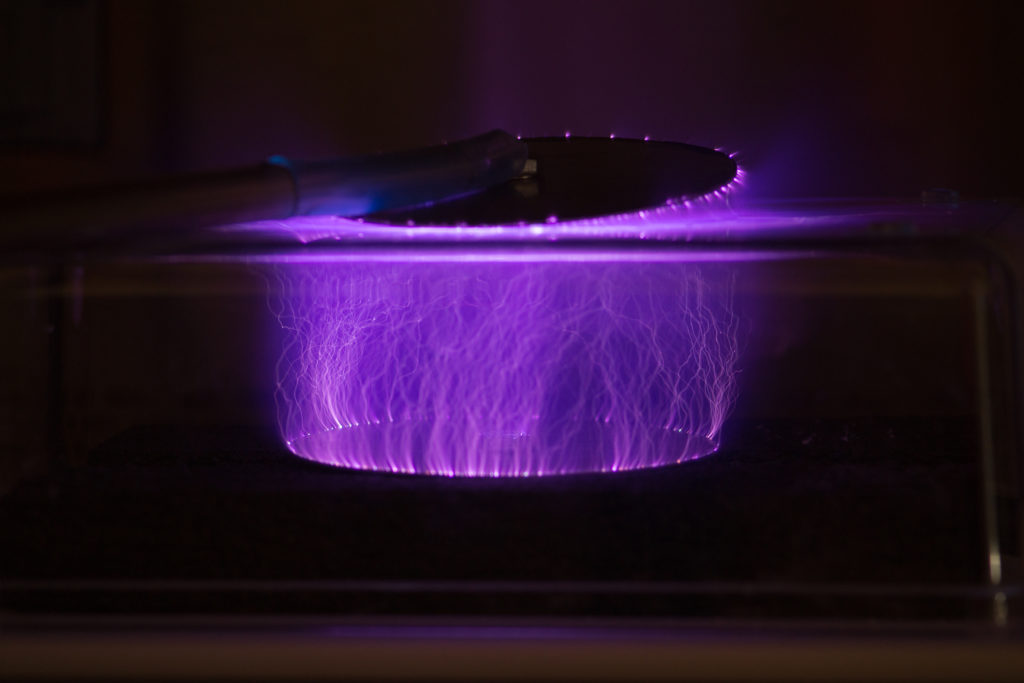

Image of Plasma field on ACP system in PHEED lab (Photo by Jessica Rae Spence)